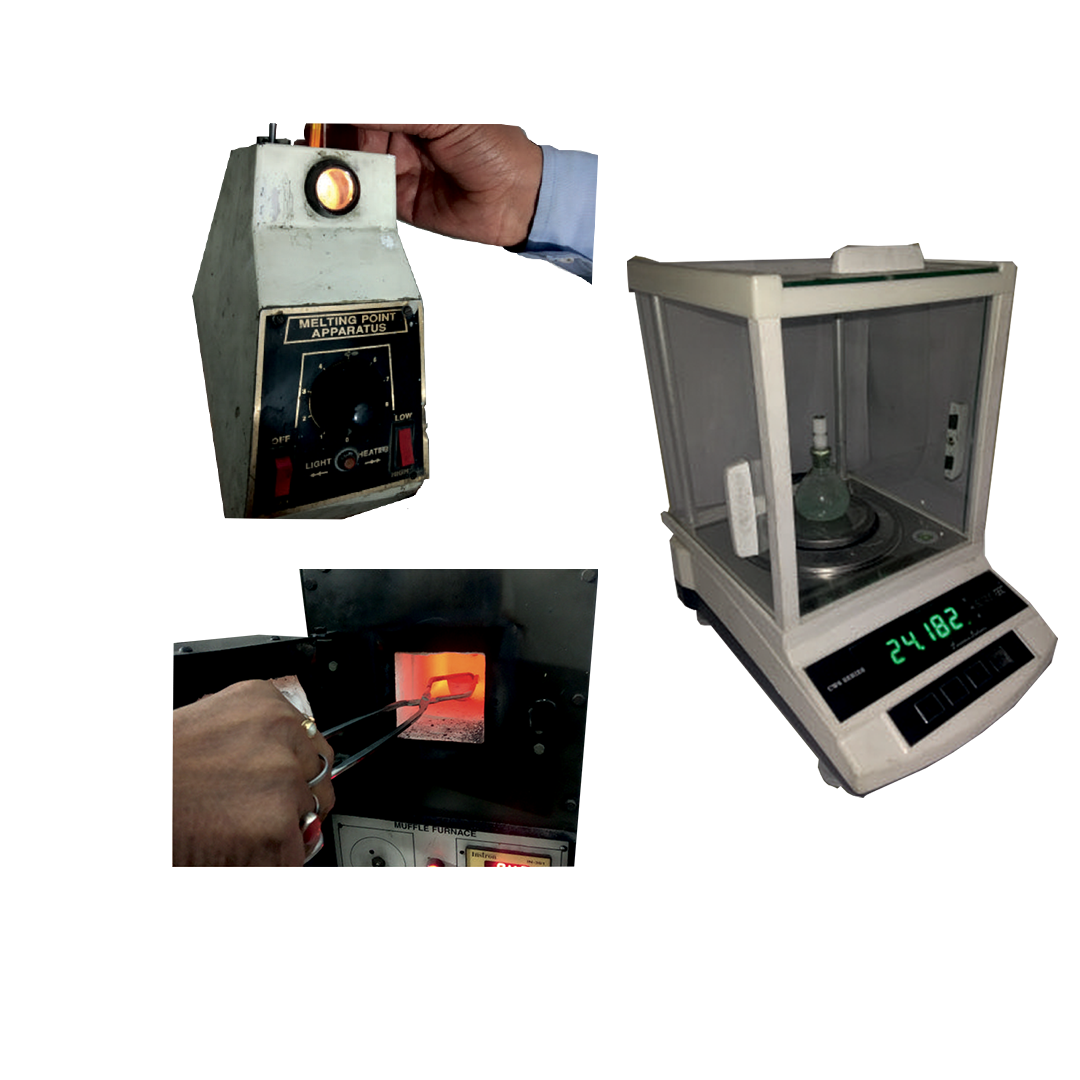

Robust’s in-house engineering research and development team conducts comprehensive

testing to analyze the friction material on a regular basis to guarantee optimal performance,

durability and dependability. Our quality assurance professionals use stat-of-the-art

technology and precise testing apparatus to perform inspections.

Strict quality control procedures are put in place at every turn in the production process from obtaining raw materials to shipping out the finished goods. Our commitment to quality is evidence of perfection and our promise to supply high quality, long lasting parts.

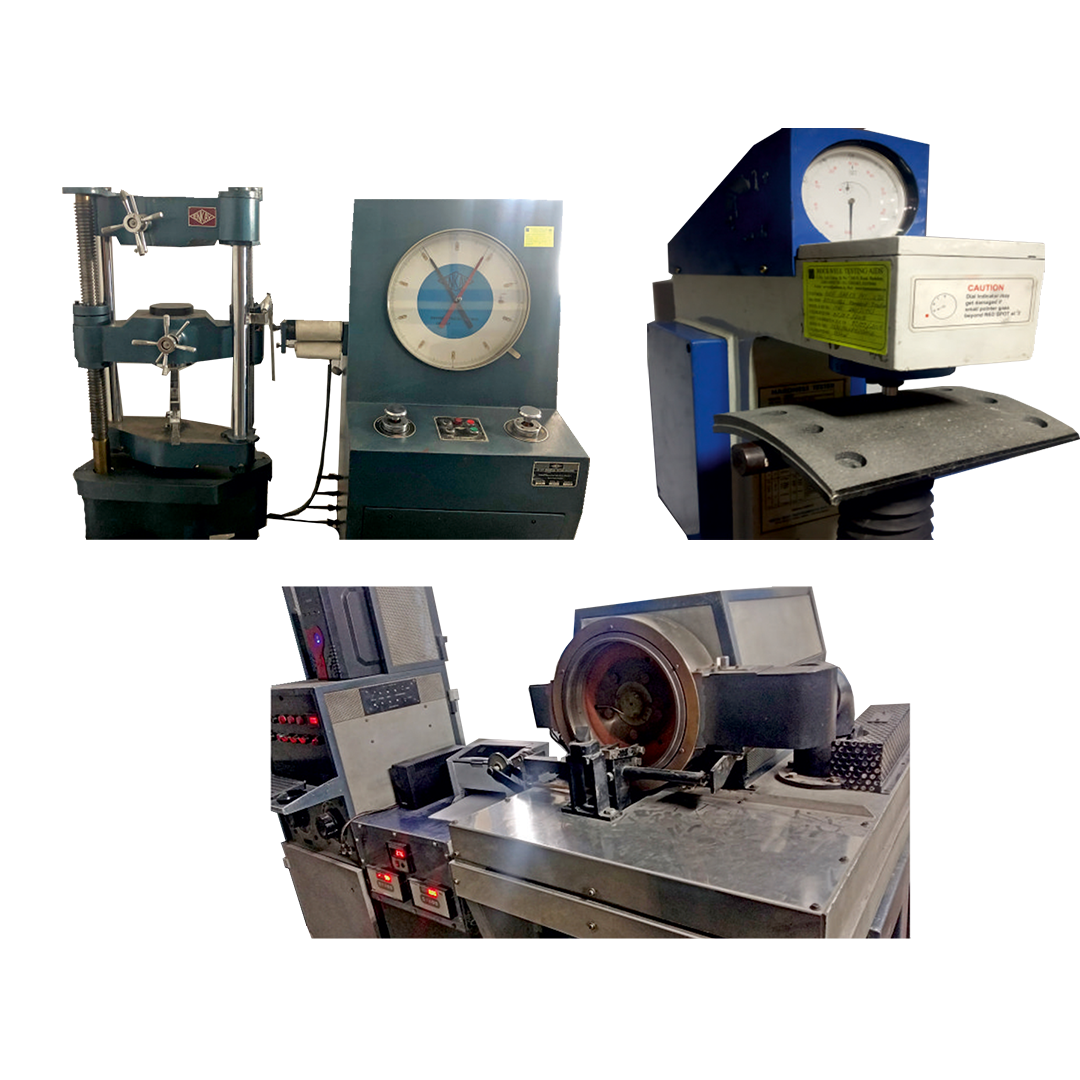

In order to achieve effective control on quality production, our production facility includes an in-house quality control department. This integrated department consists of all types of requisite test equipment including compression tester, hardness tester, chase machine, and U.T.M machine to ensure that the product meets JIS / BIS / SAE standards. Testing is carried out by our experienced quality control inspectors who inspect the finished products in order to ensure defect-free products

Strict quality control procedures are put in place at every turn in the production process from obtaining raw materials to shipping out the finished goods. Our commitment to quality is evidence of perfection and our promise to supply high quality, long lasting parts.

In order to achieve effective control on quality production, our production facility includes an in-house quality control department. This integrated department consists of all types of requisite test equipment including compression tester, hardness tester, chase machine, and U.T.M machine to ensure that the product meets JIS / BIS / SAE standards. Testing is carried out by our experienced quality control inspectors who inspect the finished products in order to ensure defect-free products

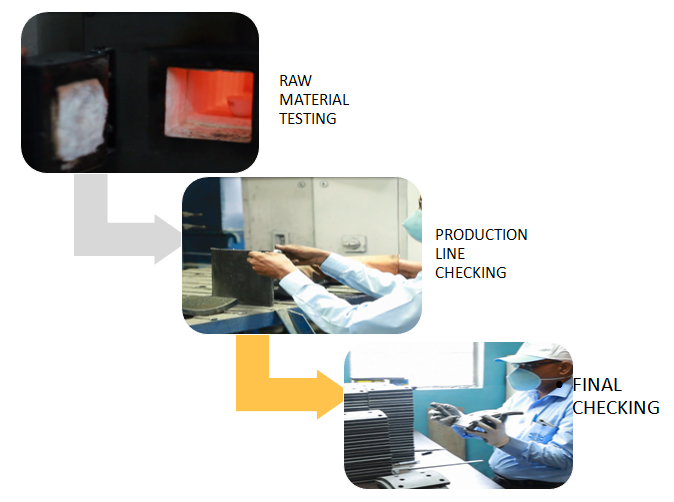

We check our product in 3 different areas on line besides Lab testing.

-

Raw Material Testing

-

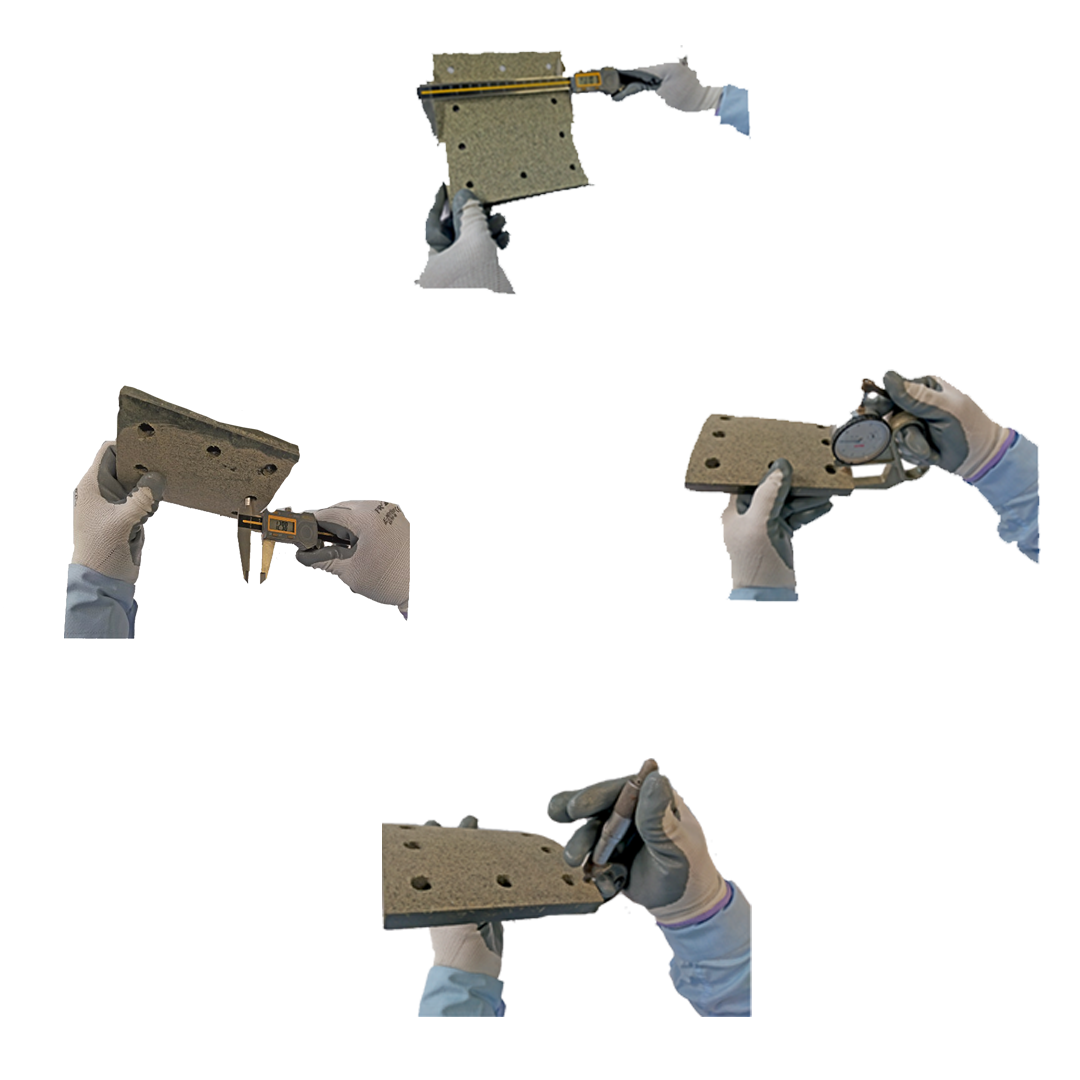

ON LINE INSPECTION

-

Final Inspection

In the inspection stage quality control parameters and eagle-eye inspection ensures that the product leaves the plant is engineered to precision. We focus on reducing the cost, increasing the productivity and enhance quality with low cost innovation by practicing kaizen.

We are dedicated to a Total Quality Management approach that measures and monitors our products and processes to ensure consistent results and continuous improvement